Plush Toys:custom plush toy Manufacturer

Custom Plush Toy

Size: customized according to the drawing

Fabric: A grade crystal super soft, PP cotton filling

MOQ: 300 pcs

40CM custom plush toys Manufacturer

40cm plush toys face duck and 15cm plush toy face duck (the first set of plush toy clothes)

40cm plush toys face duck and 15cm plush toy face duck (the second set of plush toy clothes).

The stuffed duck in the cotton doll filling department is waiting for the manual department to sew and the master to shape the doll.

The big-faced duck plush toys is quietly waiting for the plastic surgery by the master

The 15cm plush toys with small face duck in the bulk is waiting for manual plastic surgery.

You may also be interested in the following popular topics:

What are plush toys?

Plush toys are soft and stuffed toys made from materials like cotton, polyester, or other fabrics. They are often characterized by their cuddly and huggable nature.

Are plush toys suitable for all ages?

Yes, plush toys are generally suitable for all ages, from infants to adults. However, it's important to consider any small parts that may pose a choking hazard for very young children.

Can plush toys be machine washed?

Cleaning instructions vary, but many plush toys can be machine washed on a gentle cycle. Always check the care label for specific instructions.

What types of materials are used in making plush toys?

Plush toys can be made from various materials, including polyester fiberfill, cotton, synthetic fabrics, and plush or fur-like textures.

Can I customize or personalize a plush toy?

yes,customizable plush toys, allowing customers to choose colors, features, and even add personalized embroidery or names.

Do plush toys come in different sizes?

Yes, plush toys come in a wide range of sizes, from small keychain versions to giant, oversized versions.sizes sample:6cm 10cm 12cm 15cm 20cm 40cm 80cm 180cm

How do I repair a torn seam on a plush toy?

Repairing a torn seam on a plush toy usually involves sewing the seam back together. Some craft stores also sell special fabric glues for quick fixes.

Are there any allergen concerns with plush toys?

Plush toys made from hypoallergenic materials are generally safe. However, individuals with specific allergies should check the materials used in the toy.

Can plush toys be used for educational purposes?

Yes, plush toys are often used in educational settings to teach concepts like counting, colors and animal recognition, making learning more engaging for young children.

What materials are commonly used to make stuffed animals?

warmies stuffed animals are typically crafted from a variety of materials, including soft fabrics like plush, faux fur and cotton, with filling materials such as polyester fiberfill or foam.

Are there safety considerations for stuffed animals?

Yes, safety is a priority. Ensure that warmies stuffed animals are free from small parts that could pose a choking hazard, and follow age recommendations provided by manufacturers to choose age-appropriate toys.

How do I clean a stuffed animal?

Cleaning methods vary, but many warmies stuffed animals can be surface-cleaned with a mild detergent and water. Always check the care instructions on the tag or packaging for specific guidelines.

Can I machine wash stuffed animals?

Some stuffed animals are machine washable, but it's important to follow care instructions to prevent damage. Others may require handwashing or spot-cleaning for optimal care.

Do stuffed animals have any therapeutic benefits?

Stuffed animals can offer comfort and a sense of security, making them beneficial for individuals of all ages during stressful or challenging times. They can be particularly soothing for children.

Customized production process

Proofing service process:

Step 1: provide a plush toy artwork, our company will confirm the material and color of the fabric with you;

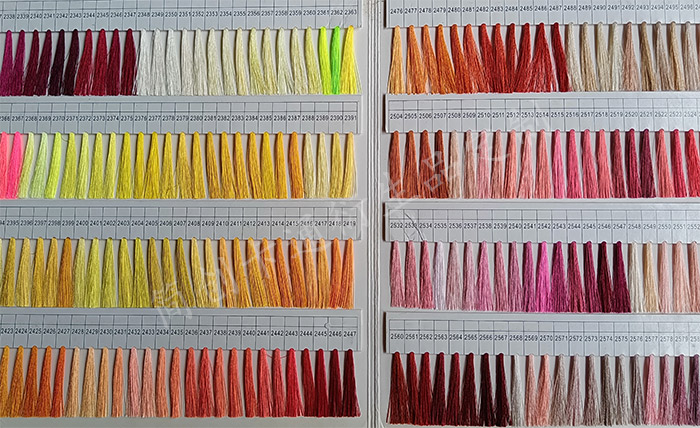

Provide three-view artwork, and the embroidery thread of the artwork is marked with Pantone color number

According to the Pantone color number of the artwork, our staff will find similar fabrics

(Provide fabric color cards for customers to choose, for more color cards, please contact our staff)

According to the Pantone color number of the artwork, choose embroidery thread of similar color (the company uses bright embroidery thread for all)

Step 2: After the proofer master is published, communicate with you remotely about the plush toys and make revisions;

Step 3: After remotely confirming that there is no problem with the plush toys, the sample will be mailed to you for final confirmation of the actual sample;

Step 4: After the plush toy sample is confirmed, send the sample back to our company for mass production order;

Step 5:The normal mass production cycle is 30 working days;

Mass production process:

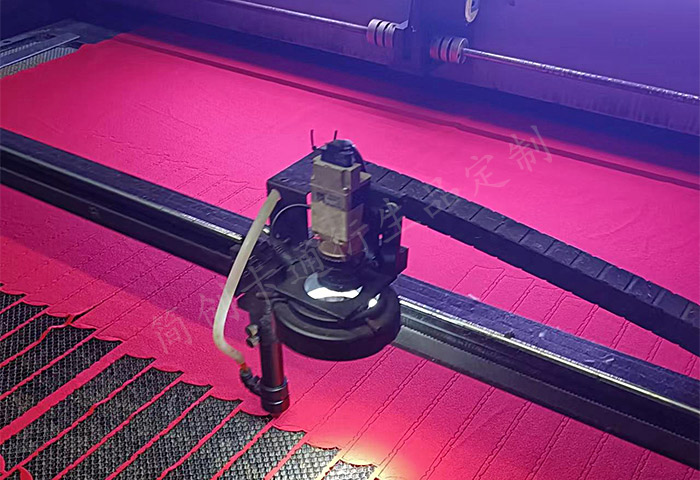

Step 6: Die cutting or laser cutting of the fabric (most fabrics can be laser cut);

Laser cutting machine in operation in laser workshop

Step 7: Enter the embroidery workshop and carry out various pattern embroidery techniques;

Embroidery machines in operation in the embroidery workshop

(ps: Embroidery machine is also called computerized embroidery machine. It is an embroidery machine with exquisite graphics for dolls. It can realize high-speed and high-efficiency traditional manual embroidery, and can realize "multi-level, multi-layered embroidery" that cannot be achieved by manual embroidery. function, unity and aesthetics" requirements.)

Step 8: Take all the processed pieces and stitch the dolls in the sewing workshop;

The sewing workshop is sewing the cut pieces. Experienced sewing hands are the greatest guarantee of quality

Step 9: After the dough is sewn, enter the cotton filling workshop to preliminarily shape the plush doll;

The cotton filling workshop is in operation

Step 10: Put the doll that has been filled with cotton into the manual workshop, sew up the filling mouth, and the plastic master will shape the doll after suturing;

The workshop is busy sewing dolls

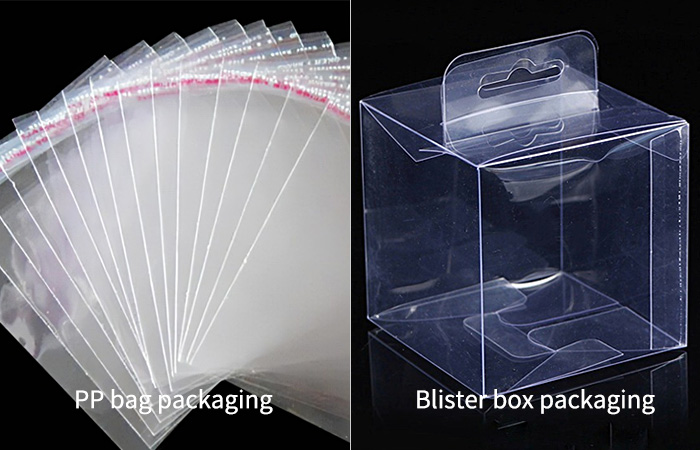

Step 11: After the master plastic surgery, after passing the quality inspection, enter the packaging workshop to formally package the dolls;

Conventional packaging: PP bag or blister box packaging, or customized carton packaging

Step 12: After packing, ship the goods. There are two ways for the factory, one is to send to the delivery point designated by the customer, and the other is to send the goods directly to the customer's address;

Step 13: After-sales service: If there is a problem in the production process of the product (all handmade products cannot be guaranteed to be exactly the same as the confirmed model), it can be repaired for free;

Real scene of toy factory production