Custom Tote Bag Factory

Custom Tote Bag

Size: customized according to the drawing

Fabric: A grade crystal super soft, PP cotton filling

MOQ: 300 pcs

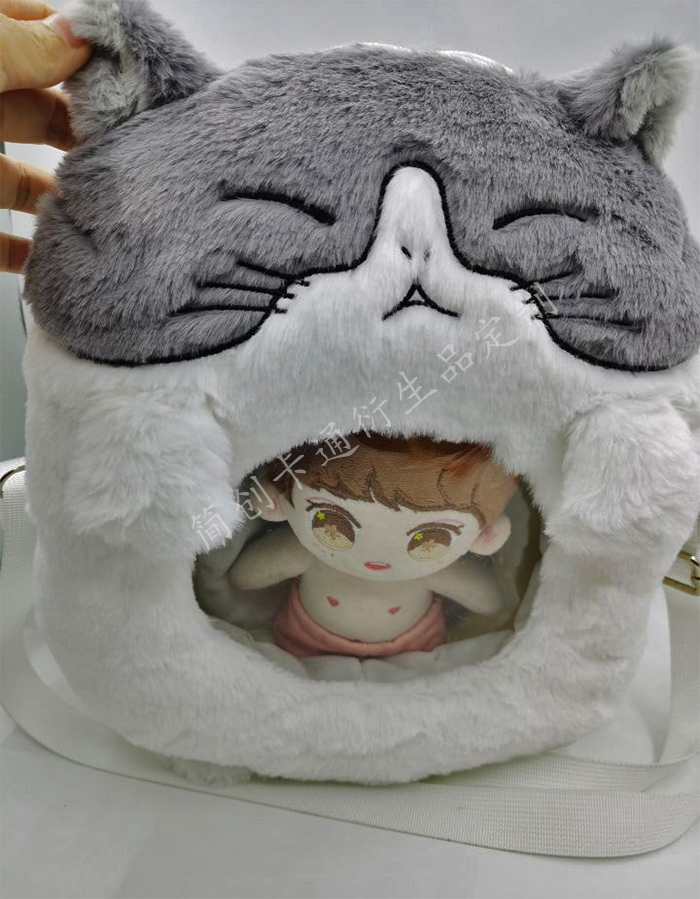

Custom 25CM shoulder bags

custom plush Baby Bag Front

custom plush doll packaging cotton doll effect

custom cotton doll bag

Custom Plush tote bag,The small thorns of the cotton doll bag are rusty and delicate

The back of the plush baby bag, super cute bag

Waiting for the quality inspector to check the goods for the last time to ensure the quality of every cotton doll bag shipped.

Customized production process

Proofing service process:

Step 1: provide tote bag artwork, our company will confirm the material and color of the fabric with you;

Provide three-view artwork, and the embroidery thread of the artwork is marked with Pantone color number

Example of three views of artwork (above)

According to the Pantone color number of the artwork, our staff will find similar fabrics

(Provide fabric color cards for customers to choose, for more color cards, please contact our staff)

According to the Pantone color number of the artwork, choose embroidery thread of similar color (the company uses bright embroidery thread for all)

Step 2: After the proofer master is published, communicate with you remotely about the tote bag and make revisions;

Step 3: After remotely confirming that there is no problem with the tote bag, the tote bag sample will be mailed to you for final confirmation of the actual sample;

Step 4: After the tote bag sample is confirmed, send the sample back to our company for mass production order;

Step 5:The normal mass production cycle is 30 working days;

Mass production process:

Step 6: Die cutting or laser cutting of the fabric (most fabrics can be laser cut);

Laser cutting machine in operation in laser workshop

Step 7: Enter the embroidery workshop and carry out various pattern embroidery techniques;

Embroidery machines in operation in the embroidery workshop

(ps: Embroidery machine is also called computerized embroidery machine. It is an embroidery machine with exquisite graphics for dolls. It can realize high-speed and high-efficiency traditional manual embroidery, and can realize "multi-level, multi-layered embroidery" that cannot be achieved by manual embroidery. function, unity and aesthetics" requirements.)

Step 8: Take all the processed pieces and stitch the dolls in the sewing workshop;

The sewing workshop is sewing the cut pieces. Experienced sewing hands are the greatest guarantee of quality

Step 9: After the dough is sewn, enter the cotton filling workshop to preliminarily shape the plush doll;

The cotton filling workshop is in operation

Step 10: Put the doll that has been filled with cotton into the manual workshop, sew up the filling mouth, and the plastic master will shape the doll after suturing;

The workshop is busy sewing dolls

Step 11: After the master plastic surgery, after passing the quality inspection, enter the packaging workshop to formally package the dolls;

Conventional packaging: PP bag or blister box packaging, or customized carton packaging

Step 12: After packing, ship the goods. There are two ways for the factory, one is to send to the delivery point designated by the customer, and the other is to send the goods directly to the customer's address;

Step 13: After-sales service: If there is a problem in the production process of the product (all handmade products cannot be guaranteed to be exactly the same as the confirmed model), it can be repaired for free;

Plush Toy Factory Introduction

The plush Toy Manufacturer has passed ISO9001:2015 international quality management system certification.

Plush toy factory bulk production scene