custom plush doll Manufacturer

custom plush dolls

Size: customized according to the drawing

Fabric: A grade crystal super soft, PP cotton filling

MOQ: 300 pcs

Custom 15CM plush dolls

15CM Star Plush Dolls,Super Cute

custom 15CM plush dolls maker

Custom plush doll clothes

Plush dolls waiting to be shaped

Packed cute plush dolls

You may also be interested in the following popular topics:

What is in a plush toy?

Plush toys typically consist of a soft outer fabric, commonly made of materials like polyester or cotton. The interior is filled with stuffing, providing the toy with its cuddly and huggable texture. The toy is assembled using seams and stitching, with additional features such as eyes and noses made from materials like plastic or embroidered fabric. The specific materials can vary based on the toy's design and manufacturer.

What is the difference between plush and soft toys?

Plush and stuffed animals are both soft, cuddly toys that can provide comfort and companionship. The main difference between the two is that plush toys are typically made from softer materials, such as velour or microfiber, while stuffed animals are usually made from denser fabrics, such as cotton or wool.

What is the purpose of plush toys?

Can squeeze their soft toy to release stress and relieve anxiety. Stroking their toy animal's fur can also calm children and reassure them that everything is alright. Over time, a beloved toy can become more and more soothing to a child.

What are the steps involved in creating a personalized custom plush dolls?

Creating a personalized custom plush dolls involves several steps, including designing the doll, selecting materials, crafting a prototype, making adjustments, sewing and assembling, quality control, and packaging. Each step is crucial to ensure that the final product matches your vision and meets quality standards.

What should I look for when choosing a reliable custom plush clothes manufacturer for my project?

When selecting a dependable custom plush clothes manufacturer for your project, consider factors such as their experience, portfolio of past work, production capabilities, quality control processes, communication, pricing, and reviews from previous clients to ensure a successful and satisfactory collaboration.

How can I turn my unique character idea into a custom plush doll?

To transform your unique character idea into a custom plush doll, you can collaborate with a skilled plush maker. Begin by sharing detailed sketches or descriptions of your character's appearance, colors, and features. Work together to refine the design, choose suitable fabrics, and determine the size. Regular communication and feedback will ensure the plush doll matches your vision, resulting in a delightful and personalized creation.

What are the different customization options available for doll plush creations?

The customization options for doll plush creations are extensive, including choices for size, materials, clothing, facial features, hair, colors, and even personalized embroidery or accessories. These options allow you to craft a doll plush that perfectly embodies your vision and brings your imagination to life.

What makes star plush dolls a popular choice among children and collectors alike?

Star plush dolls are popular among both children and collectors due to their whimsical and celestial appeal. Their enchanting designs, often featuring stars, moons, and cosmic elements, capture imaginations and evoke a sense of wonder. For children, these plush toys offer a comforting connection to the night sky, while collectors are drawn to their unique and artistic representations of the universe.

Customized production process

Proofing service process:

Step 1: provide a plush dolls artwork, our company will confirm the material and color of the fabric with you;

Provide three-view artwork, and the embroidery thread of the artwork is marked with Pantone color number

Example of three views of artwork (above)

According to the Pantone color number of the artwork, our staff will find similar fabrics

(Provide fabric color cards for customers to choose, for more color cards, please contact our staff)

According to the Pantone color number of the artwork, choose embroidery thread of similar color (the company uses bright embroidery thread for all)

Step 2: After the proofer master is published, communicate with you remotely about the plush doll and make revisions;

Step 3: After remotely confirming that there is no problem with the plush doll, the sample will be mailed to you for final confirmation of the actual sample;

Step 4: After the plush dolls sample is confirmed, send the sample back to our company for mass production order;

Step 5:The normal mass production cycle is 30 working days;

Mass production process:

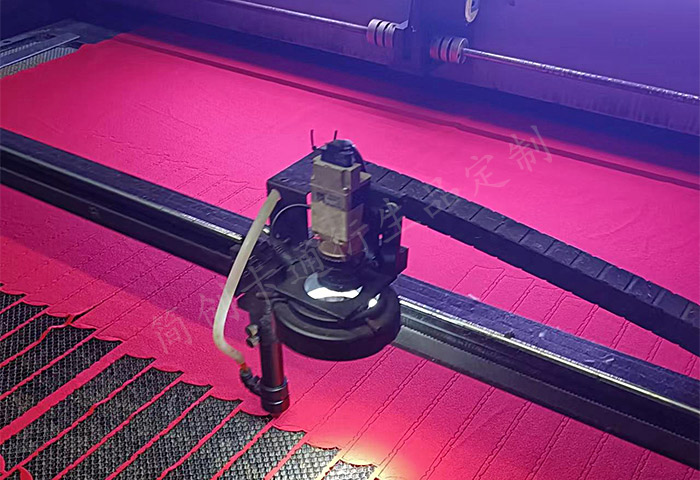

Step 6: Die cutting or laser cutting of the fabric (most fabrics can be laser cut);

Laser cutting machine in operation in laser workshop

Step 7: Enter the embroidery workshop and carry out various pattern embroidery techniques;

Step 6: Die cutting or laser cutting of the fabric (most fabrics can be laser cut);

Laser cutting machine in operation in laser workshop

Step 7: Enter the embroidery workshop and carry out various pattern embroidery techniques;

Embroidery machines in operation in the embroidery workshop

(ps: Embroidery machine is also called computerized embroidery machine. It is an embroidery machine with exquisite graphics for dolls. It can realize high-speed and high-efficiency traditional manual embroidery, and can realize "multi-level, multi-layered embroidery" that cannot be achieved by manual embroidery. function, unity and aesthetics" requirements.)

Step 8: Take all the processed pieces and stitch the dolls in the sewing workshop;

The sewing workshop is sewing the cut pieces. Experienced sewing hands are the greatest guarantee of quality

Step 9: After the dough is sewn, enter the cotton filling workshop to preliminarily shape the plush doll;

The cotton filling workshop is in operation

Step 10: Put the doll that has been filled with cotton into the manual workshop, sew up the filling mouth, and the plastic master will shape the doll after suturing;

The workshop is busy sewing dolls

Step 11: After the master plastic surgery, after passing the quality inspection, enter the packaging workshop to formally package the dolls;

Conventional packaging: PP bag or blister box packaging, or customized carton packaging

Step 12: After packing, ship the goods. There are two ways for the factory, one is to send to the delivery point designated by the customer, and the other is to send the goods directly to the customer's address;

Step 13: After-sales service: If there is a problem in the production process of the product (all handmade products cannot be guaranteed to be exactly the same as the confirmed model), it can be repaired for free;

Plush Toy Factory Introduction

The plush Toy Manufacturer has passed ISO9001:2015 international quality management system certification.

Plush toy factory bulk production scene