The cost of making plushies depends on several factors, including materials, size, design complexity, manufacturing method, and production quantity. Whether you are making a single plush toy or ordering in bulk, understanding these factors can help determine if plushies are expensive to produce.

1. Materials and Fabric Quality

The type of fabric used significantly affects the cost. Common plush materials include:

-

Short plush & minky fabric – Soft, affordable, and widely used.

-

Faux fur – More expensive due to its texture and difficulty in sewing.

-

Specialty fabrics (velvet, fleece, or cotton blends) – Can increase costs depending on the level of customization.

-

Filling (PP cotton, memory foam, or weighted beads) – Higher-quality fillings offer better durability and texture but cost more.

Higher-end plushies, such as collector’s edition or limited-edition toys, often use premium materials, making them more expensive.

2. Design Complexity and Customization

Simple plushies with minimal embroidery and standard shapes are cheaper to produce. However, if a plushie has:

-

Detailed embroidery (eyes, logos, patterns)

-

Multiple fabric layers or color variations

-

Accessories (clothes, hats, or props)

-

Unusual shapes or jointed limbs

It will require more labor and advanced manufacturing techniques, increasing the cost.

3. Manufacturing Method

If you are producing a plushie on a small scale (one-off or handmade), it will be more expensive due to the labor-intensive process. Handmade plush toys from independent artists can range from $50 to $200 depending on complexity.

On the other hand, mass production significantly reduces the cost per unit. Large-scale plush manufacturers (factories in China, Vietnam, etc.) offer lower costs, but they require bulk orders with minimum order quantities (MOQs). Typically, bulk pricing per plushie ranges from $3 to $15 depending on size and complexity.

4. Prototyping and Setup Fees

For custom plush toys, manufacturers usually charge a prototyping fee ranging from $100 to $500. This fee covers material sourcing, pattern creation, and initial sample production. Once the design is finalized, mass production becomes more cost-effective.

5. Packaging and Shipping Costs

Additional expenses like custom packaging, branding tags, and international shipping can impact overall costs. Plush toys are lightweight but can take up significant space, increasing shipping costs for bulk orders.

Conclusion

Plushies can be expensive to make, especially for small-scale custom designs. However, mass production significantly reduces costs. If you want a unique, high-quality plushie, expect to pay more for materials, design, and labor. Planning ahead and considering bulk orders can help lower production expenses.

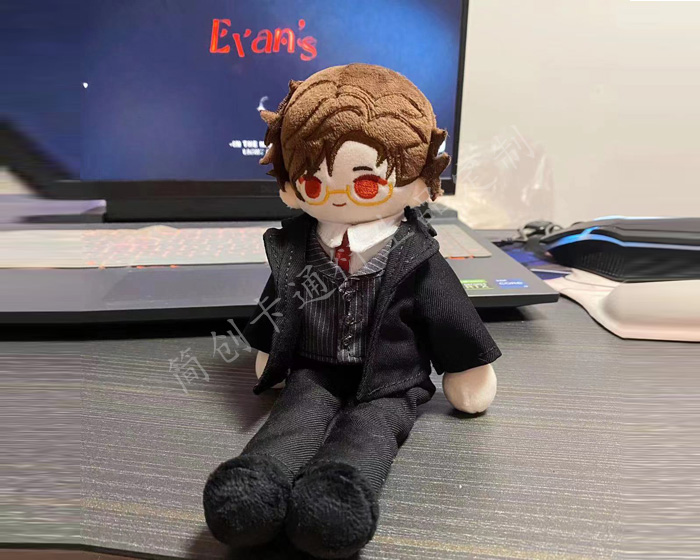

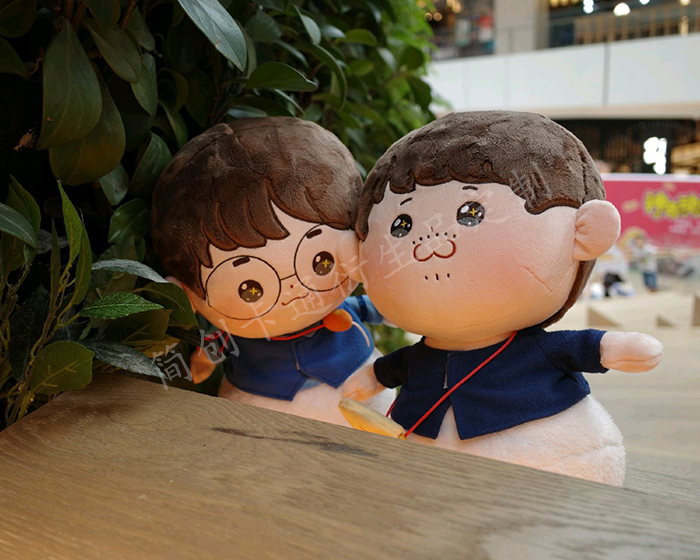

The following are some examples of plush toys that our factory customizes for customers. Check out if there is one that you like best.

-

Custom Animal Plush

-

Cute Plush Doll

-

Custom Stuffed Animals

-

Plush Toy

-

Plush Dolls

-

Custom Stuffed Dolls

-

Custom Plush Toy

-

Cotton Dolls

-

Weighted Plush Toys

-

Cute Stuffed Animals

-

Custom Pet Stuffed Animal

-

Warmies Stuffed Animals

-

Weighted Stuffed Animal

-

Soft Toys

-

Plush Stuffed Doll

-

Custom Stuffed Dolls

-

Plush Maker

-

Bear Stuffed Toy

-

Anime Plush

-

Custom Stuffed Animal

-

Anime Plush

-

Custom Plush Toy

-

Personalised Stuffed Animal

-

Plush Animal Toys

-

Custom Plush Makers

-

Custom Plushies

-

Toy Manufacturer

-

Rag Doll Making

-

Custom Toys

-

Dog Plush Toys

-

Custom Rag Doll

-

Stuffed Animals

-

Custom Plush

-

Custom Plush Dolls

-

20cm Cotton Doll

-

Jojo Plush

-

Custom Doll

-

Jojo Doll

-

Large Plush Toys

-

15cm Cotton Doll

-

Dumpling Plush

-

Cotton Doll