Manufacturing stuffed animals toys is a complex yet rewarding process that involves several steps, from design to production and quality control. Whether you're a small business owner or part of a large company, understanding the manufacturing process is crucial to creating high-quality products. Here's a comprehensive guide on how to manufacture stuffed toys.

Step-by-Step Guide:

Design and Prototyping

Conceptualization: Start with a clear idea of the stuffed animals toy you want to create. This includes the character, size, features, and overall appearance.

Sketching and Digital Design: Create detailed sketches or use digital design software to bring your concept to life. This helps in visualizing the final product and making necessary adjustments.

Pattern Making: Develop patterns for each part of the toy. Patterns are templates that will be used to cut the fabric. Precision in pattern making is essential for consistency in production.

Prototype Creation: Using the patterns, create a prototype of the Stuffed Animals toy. This initial model helps in identifying any design flaws or areas for improvement before mass production.

Material Selection

Fabrics: Choose high-quality fabrics such as plush, fleece, minky, or felt. The fabric should be soft, durable, and safe for children.

Stuffing: Polyester fiberfill is commonly used for stuffing. It should be hypoallergenic and compliant with safety standards.

Additional Materials: Select threads, embroidery floss, safety eyes, buttons, and any other materials needed for detailing the toy.

Cutting and Sewing

Cutting: Lay the fabric flat and use the patterns to cut out the pieces. Industrial fabric cutting machines can improve efficiency and precision.

Sewing: Sew the cut fabric pieces together. Industrial sewing machines are often used for speed and consistency. Leave small openings for stuffing.

Detailing: Add embroidered details, sew on eyes, noses, and other features. This step can be done manually or with specialized embroidery machines.

Stuffing and Assembly

Stuffing: Fill the sewn pieces with polyester fiberfill. Ensure even distribution of stuffing for a uniform look and feel.

Assembly: Hand-sew or machine-sew the openings closed. Assemble the stuffed toy by attaching limbs, ears, tails, or other parts as needed.

Quality Control

Packaging: Package the stuffed toys in suitable packaging. This can include plastic bags, boxes, or custom-designed packaging that reflects the brand.

Labeling: Include necessary labels with safety warnings, material information, and care instructions.

Distribution: Plan the distribution logistics, including shipping methods, storage, and inventory management. Partner with reliable shipping companies to ensure timely delivery.

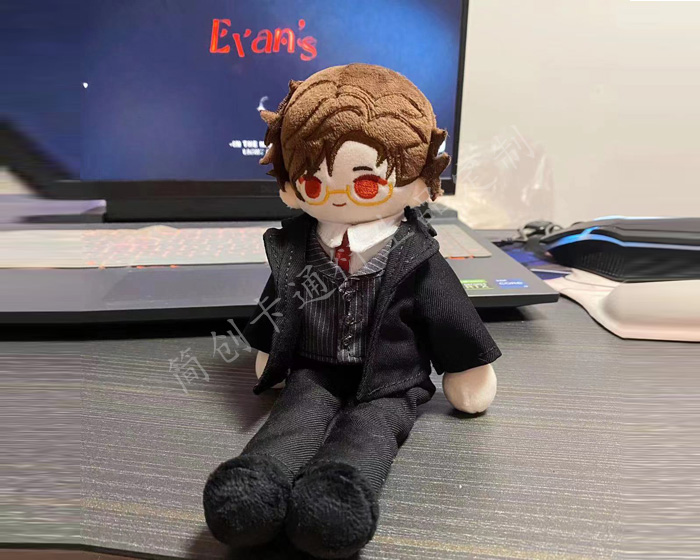

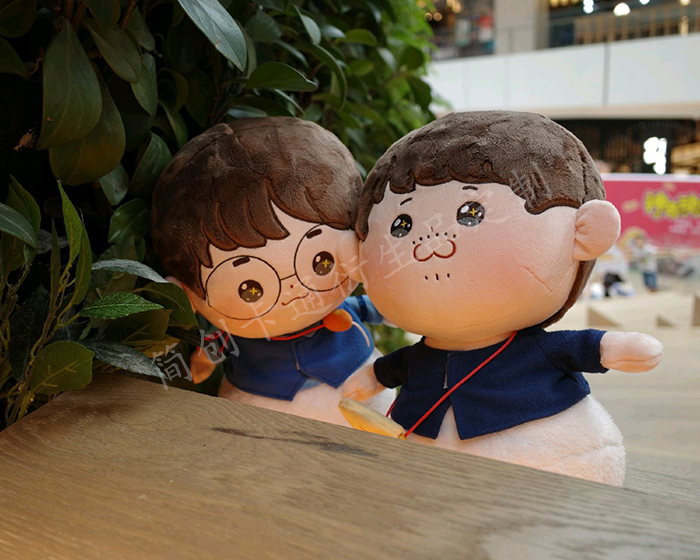

The following are some examples of plush toys that our factory customizes for customers. Check out if there is one that you like best.

-

Custom Stuffed Animals

-

Plush Toy

-

Plush Dolls

-

Custom Animal Plush

-

Cute Plush Doll

-

Custom Stuffed Dolls

-

Custom Plush Toy

-

Cotton Dolls

-

Weighted Plush Toys

-

Cute Stuffed Animals

-

Custom Pet Stuffed Animal

-

Warmies Stuffed Animals

-

Weighted Stuffed Animal

-

Soft Toys

-

Plush Stuffed Doll

-

Custom Stuffed Dolls

-

Plush Maker

-

Bear Stuffed Toy

-

Anime Plush

-

Custom Stuffed Animal

-

Anime Plush

-

Custom Plush Toy

-

Personalised Stuffed Animal

-

Plush Animal Toys

-

Custom Plush Makers

-

Custom Plushies

-

Toy Manufacturer

-

Rag Doll Making

-

Custom Toys

-

Dog Plush Toys

-

Custom Rag Doll

-

Stuffed Animals

-

Custom Plush

-

Custom Plush Dolls

-

20cm Cotton Doll

-

Jojo Plush

-

Custom Doll

-

Jojo Doll

-

Large Plush Toys

-

15cm Cotton Doll

-

Dumpling Plush

-

Cotton Doll